Te strzałki symbolizują bodajże wektory mocy czynnej i biernej, wyświetlają się zależnie od kierunku przepływu energii (dla biernej zależnie od tego czy przeważa “pojemnościowa” czy “indukcyjna”).

@szopen

Tak sobie właśnie myślałem, ale nie miałem pewności.

@GSzabados

Thanks a lot for the info on this meter. I guess, based on the documentation, we could at least verify what those icons on the LCD display mean to further analyze my case. We’ll see how it goes. I wish I could have avoided this and it simply work with no issues.

I would keep trying to activate it. Especially during the night or early in the morning, when less power is used from the grid.

I am more concerned about this icon, and the fact that nobody talks about it. Especially not the DSOs.

That is the icon of the remote disconnector. Most of the smart/remote reading meters are equipped with it. Basically the DSO can remotely disconnect the end-user.

The reasoning or wording for it is usually grid stabilisation. But if you read some interesting cyber security articles, you will find descriptions how a complete grid can be destabilised by turning on and off consumers with the right frequency (timing).

By the way, this is the Hungarian leaflet for the Holley meter:

And some manuals for the Holley Techologies meters with the same case as the NES Type 73331:

It gives you an idea how the meter works and what data it shares. Unfortunatelly it does not contain information on the AMIPlus or W-MBus.

Thank you so much @GSzabados. Interestingly enough, no mention on any communication done over the power line. Oh well… I think I will set up an older cell phone in front of the meter and look for any changes in the PLC signal strength indicator to find out when it gets better (if at all). We’ll keep you posted.

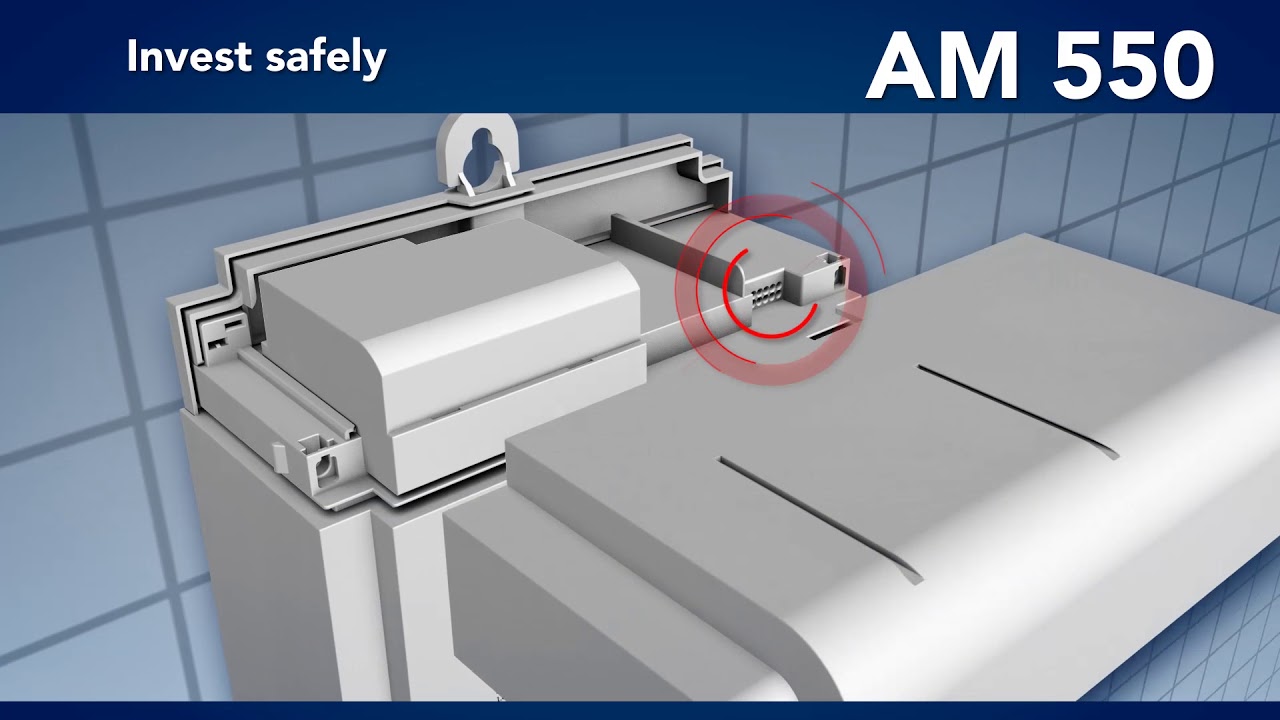

All the communication on any of the smart meters done on a modular basis. Just as an example here is an Iskra AM550 ad video explaining the modularity of it.

Yes, @GSzabados - all OK. I bet this PLC in use is based on some standardized protocol / communication stack. Just don’t know which one it is.

By the way: I wonder if this noise / interference I am experiencing is caused by the leakage in a reverse direction through the meter of several PLC devices I use in the house. Currently I have four of such plug-in boxes in use and - from the old checks I did in a different house and different set of PLC devices - the noise was very high and everywhere in the spectrum.

I tired disconnecting all circuits behind (i.e. after) the meter - no real change, sadly. But I shall try it one more time - something tells me it takes time before the status is updated on the meter (I tend to think - 10 minutes or more before I see any change).

@pswiatki, here is another good read about PLC.

As you mention that you have PLC devices in the house, isn’t the House icon disappear when you unplug all of them? I could imagine that it was really meant for an IHD communicating on PLC. And maybe the meter misinterprets the PLC from the house side.

My previous experience with PLC network adapters was terrible. They do work when they are in the same room, but beyond that, it is more like a hit and miss. Especially for higher bandwidth. And you need to be sure that the sockets are on the same phase otherwise they stop working. Do you use TP-Link ones?

PLC technology used by AMI meters (band A under 100kHz) is NOT the same PLC technology as used in standards like HomePlug 1.0/AV/AV2 (bands from 2 MHz to ~100MHz).

Thanks to the different RF bands used, the signals of these standards do not even interfere, and the only common element is the transmission medium, which is electrical cables.

Aha! Makes sense. Thanks a lot for giving out some interesting technical details.

@GSzabados I used to work with TP-Link PLC devices and they were OK. Not sure if I was just lucky (and all of the power outlets were on the same phase) or somehow the devices worked across phases, but had no issue getting up to 70-80 Mbps (much less than advertised, but good enough). Now I use a different set of boxes from some major provider in one of the Benelux countries.

I will add more details later. These new devices reach similar top speeds, but they nicely bridge Wi-Fi (2.4 and 5.0 GHz) with Ethernet, so I find them useful. Also, they are (as used devices) much cheaper than TP-Link models.

That much I could get always, even more from Wifi, but that was the point to have above than 200Mbps.

I got all of mine from Allegro as second hand, so they were fairly cheap. ![]()

Some like this, or there is an upgraded version which capable of 2Gbps as I remember. But the best which I get out of it was like 600Mbps in the same room which was doable by cable.

The 2Gbps version:

@GSzabados Well, given the power lines in this house and their wacky setup here - I am happy that it works and I can at least get this speed.

These are the PLC interfaces I currently use:

PowerLine PG-9073LG-TN and PG-9072LG-TN (the latter with Wi-Fi).

They are also known as Comtrend (the manufacturer?).

Now, the same Allergo seller has newer devices from the same source, I think:

Comtrend PG-9082LG-TN/PG-9083LG-TN.

The logo on those bosses reminds me of UPC cable TV / Internet provider.

I have not met yet an electrician in Poland who I would trust. ![]()

The guy, who installed the PV, had originally political studies and was a spokeperson for years for a bigger city’s public transport company, as I found it out later on. But he tried to explained me (to my wife) that the app/website of the inverter shows production incorrectly from the grid, because the DSO has to change the utility meter, and after it will be correct. He just wired the smart meter of the inverter the opposite way around… ![]()

True ![]()

I use Strong POWERL500DUOFR french version (IEC type E sockets), which was cheapest solution for me at the time when I needed it - four-pack (=2x two-packs) under 40€.

It is advertised as 500Mbs (very funny, as it has 100Mbs Ethernet port) but this is typical practice when it comes to technologies related to WiFi (like PLC), where speeds are shown in the hardware layer that are not available to the user. In fact it is working really stable with real speeds about 80Mbps up/down.

European version (in fact it should not be sold in Poland, as it uses IEC type F sockets = Schuko)

It is PLC HomePlug AV standard (bands beetween 2MHz and 68MHz).

Over 20 years ago I used Intel Anypoint Phoneline Home Network cards (it was using standard phonelines 2-wire infrastructure to build Ethernet network 1Mbps), it was the forerunner of PLC technology.

BUT we should separate PLC (HomePlug/HomePNA) thread to another topic, as is has nothing to do with AMI meters…

Let’s do it - again. Please separate this PLC topic to a new thread and I shall update my messages there. Thanks a bunch!

The problem is the multiple aspects of the noise.

Generally bad construction of the power line network can cause reflections. About 20 years ago a friend of mine who was studying to be an electrical engineer or mechanical/infrastructural engineer, expalined me how it works regarding reflections and how much effort is put in to deal with it, especially with high voltage and long cables.

The article (pdf) which I linked, explaines how often repeaters has to be placed and how older switch power supplies/adapters can cause noise on the network. It must be the same with home use PLC adapters. The meter should filter everything out, but it does not. A 100Mhz signal can be easily sampled as a 50Mhz one or any of its harmonics. Might not be a lot, but it adds up from multiple source.

If I would bet, I would put my money on some old fridges in the neighbourhood and the repeater meters being on different phases than yours for PLC communication.

Of course, there are many sources of noise, but I don’t think the PLC (HomePlug, etc.) can be the main source of the problem because many variations of PLC standards are designed to coexist on the same lines.

I have read a brochure summarizing the Austrian experiments, but it contains many simplifications, and the actual condition at the installation site could only be checked using a frequency analyzer or other dedicated equipment.

@pswiatki showed interesting photos - old AMI meter had better PLC signal that current…

so the most suspicious people are the operator technicians who replace the meter ![]()

This may be true, but I wonder what the technician did incorrectly - I watched him replace the meter and nothing was out of the ordinary. It was this forum where I found information about potentially problematic firmware in some meters. So, who knows, maybe this NES AMIPlus meter in its current version has some problems on either the PLC side, the mBUS side, or both.

He hasn’t done anything incorrectly. It is just coincidence, because most likely they are absolutely unaware how the meter is working. ENEA employs literally idiots. And I am not joking. They have no interest to know anything about the equipment what they are installing, they just know that they have to connect cables on the bottom to input and output and then seal it.

ENEA instructed the installers to seal the P1 port on the OTUS 3 meters. Which supposed to be a communication port for end clients. Obviously they can’t do the same on an Iskra AM550, because that is just a rubber plug, and the manufacturers has not made any effort to provide sealing holes on it, because it is not intended to be sealed off.

So, this is most likely what has happened, if I would guess.

The 3-phase PLC repeater or data collector is too far away and the line is noisy. The nearest meters which supposed to be repeating, most likely using another phase for PLC communication.

So, lets say, from the meter’s perspective L1 is the PLC communication port. Your previous meter had L1 as PLC communication port as well. But when the cables were disconnected the cable from L1 has been connected to the new meter’s L2 port and the cable from L2 has been connected to L1. So now the new meter is communicating on a different cable than before.

I really doubt that the technician checked how are the signal levels for PLC on each cable before connected it to the meter, just to ensure optimal conditions for the meter’s PLC communication.

And just to understand my comments about the installers (just read it along from that comment, it is a really interesting subject):

https://www.elektroda.pl/rtvforum/viewtopic.php?p=18875286#18875286

Well, not really, no. If that was the case then the communication would be very sketchy. However, it seems I can get data online (eLicznik) every day and they match the readout on the meter. Even the hourly report looks legit hour by hour. So, they probably do get something over the PLC port.

Now, to further comment on the issue:

I tried what you suggested before - after shutting down the power in the entire house I went to the cellar early in the morning:

2 out of 3 bars lit. After 3 minutes the quality indicator goes 3/3, so full scale:

So, this was a good sign. However:

So, it is some other issue, I am afraid.

By the way: as soon as I brought the power back to the entire house - the quality immediately returned to marginal (1 of 3 bars).

No chance for that, either. Those were solid copper thick wires. Very stiff. I guess 4 mm². So, they barely moved when the old meter was taken off the wall.

Something tells me it is something with that new meter that is problematic. It is probably sensitive to interference on the PLC interface and the mBUS port is dysfunctional (at least: no way to activate it remotely).

This is now becoming ridiculous. That is: TAURON is.

Check this, guys:

Sweet - so I grabbed the address and the key and went to my wmbusmeters setup with it.

No reception. Telegrams with this ID never showed up. The LCD on the meter showed no bars next to the house icon and all three bars next to the pole icon. It seems they massively improved the PLC side, perhaps even sent the commands to activate the wMBUS transmitter, but that did not succeed, I am afraid.

That was the status yesterday. Now, I have just come back from the cellar and can report the older situation is back. That is: no signal bars for wMBUS and only one for PLC.

So, one or the other - massive problems with the infrastructure (not excluding the software of the meter itself), or major incompetence of the staff @TAURON… or BOTH.